Manufacturers across the country are dealing with supply chain issues, production constraints, and other hurdles that make it difficult to meet consumer demand for specific products. 3D printing manufacturing is a growing trend that helps manufacturers in certain industries produce parts and products on demand.

In 2022, the global 3D printing market had a value of $18.33 billion, and experts predict it will grow to over $105 billion by 2030.

The benefits of different applications of 3D printing in manufacturing include the speed of production and delivery, the ability to print certain parts and products as customers order them, customization options, and reduced cost of materials. Traditional manufacturing is often a subtractive process, resulting in more waste than new 3D printing techniques, which are often additive.

How Does 3D Printing Contribute to Manufacturing Processes in Different Industries?

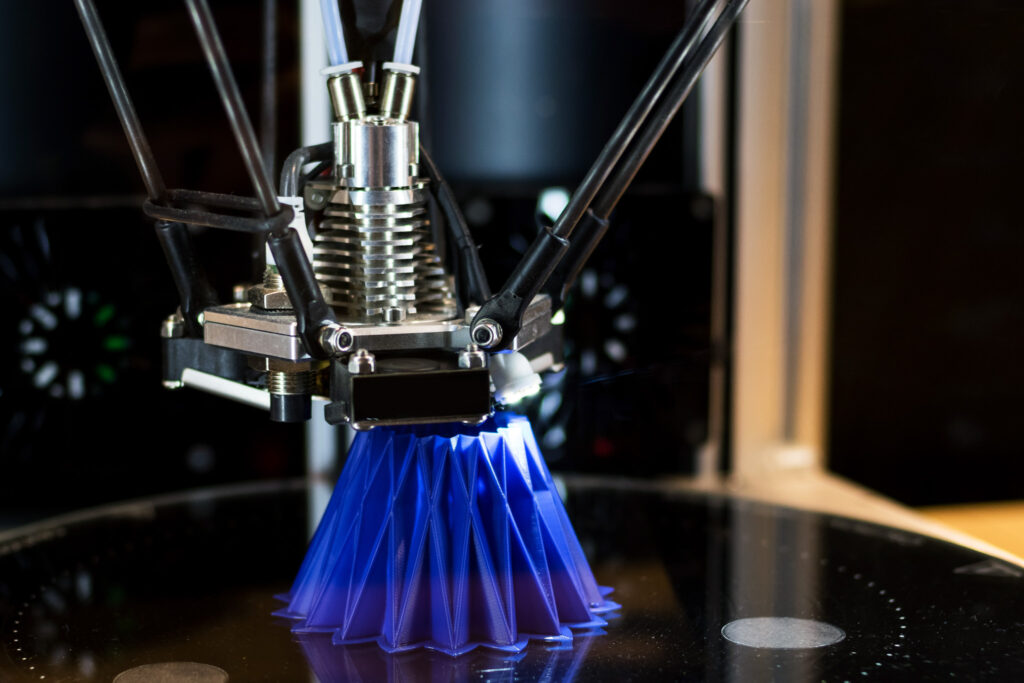

Plastics, metals, concrete, wood pulp, and other materials are now printable using stacking designs with 3D printing. Metal parts fabrication, new home and office building construction, and automotive manufacturing are just some of the industries implementing industrial 3D printing to build parts and structures.

But what makes 3D printing different from traditional manufacturing processes? Traditional manufacturing involves several constraints in form, such as the geometries of holes and mesh frames for support inside of manufactured parts. With 3D printing, the printer can lay shapes on flat surfaces and build each layer using complex shapes and structures.

Because 3D printing involves adding materials to build shapes, it produces less waste than traditional manufacturing, which involves cutting shapes from metal sheets or similar materials. Additionally, 3D printers can produce perfect turns, curves, corners, and other shapes in the final design rather than requiring post-production work with bending tools. You can even print interior honeycomb or triangle support patterns inside your parts.

Several industries are turning to 3D printing for manufacturing, including:

- Aerospace engineering

- Defense contracting

- Automotive manufacturing

- Home and commercial construction

- Medical and dental equipment manufacturing

- Industrial parts manufacturing

Low-Volume Manufacturing vs. High-Volume Manufacturing

Low-volume manufacturing includes short-run production for prototypes or small batches of a limited number of parts. When producers develop a new product or offer high customization services for specific offerings, being able to produce a small number of products on demand quickly is essential. 3D printing manufacturing offers an agile development process for new or custom product design and production.

High-volume manufacturing can also benefit from 3D printing. Production and manufacturing processes that implement 3D printing can update equipment arrangements on the production floor much faster than traditional manufacturing equipment, improving workflows in a matter of hours instead of days or weeks.

Potential Benefits of 3D Printing for Manufacturing

Even if you know the benefits of this technology, you may not know how to take advantage of 3D printing applications for your parts and products. Can your company’s bottom line benefit from implementing 3D printing? 3D printing is less wasteful, more affordable, faster, and comes with fewer risks than traditional manufacturing processes.

Reduced Manufacturing Costs

3D printing is cost-effective and reduces waste. It is especially effective in creating lightweight parts for industries like aerospace and technology while reducing the amount of raw materials necessary to produce a part.

The additive manufacturing process allows for cost reduction compared to traditional manufacturing methods. Additionally, rather than having to manufacture more parts and assemble them separately, 3D printing allows manufacturers to consolidate separate parts into a single component, requiring fewer steps, materials, and labor hours.

Faster Time to Market

In industries at the leading edge of ingenuity, the time it takes to develop working prototypes for testing, troubleshooting, and adjusting can lead to delays in getting new products to market. Reducing the time to market with fast prototyping and initial launch production manufacturing with 3D printing can help you recover your initial investment in the new product sooner.

Launching a new product is costly, requiring initial product runs, advertising, and storage until launch. You also need to sell retailers on the idea of the new product before you can put your product in front of your normal consumers. With a faster time to market, you have less risk in your return on investment (ROI).

In fact, 68% of companies that use 3D printing have integrated it with their prototyping and pre-series manufacturing processes.

Improved Risk Mitigation in Prototype Development

Creating a new product or redesigning an existing product design comes with inherent risks of failure. Faster, more affordable prototype manufacturing with 3D printing allows your engineers to test multiple design features at once by running different variables on multiple printers.

If you only have one printer available, setting up separate runs is much simpler than on traditional CNC punch or bending equipment. Simply upload your next design and ensure that the print parameters for material and flow volume are appropriate for your next part. This ease of use in 3D printing equipment is key in risk mitigation compared to the lengthy process of prototype production using traditional manufacturing methods.

Increased Flexibility in Design

The additive design features of 3D printing allow for greater flexibility in design. The printer can build internal structures as a single molded part rather than requiring multi-part construction that combines multiple geometries into a part through several production steps. Something like turning a square hole into a triangle on either end of a tube is simple with 3D printing technology.

Reduced Material Waste

Printing materials stacked in layers to form a single part is an additive process. Workers or warehouse robots don’t need to cut liquid or spooled materials from a larger piece of material. Traditional manufacturing is subtractive and produces costly scrap waste.

Learn More About Industrial 3D Printing on the Encore Deliveries Blog

If you’re considering 3D printing manufacturing processes for your company, visit the Encore Deliveries blog to learn more about trends in 3D printing for manufacturing and how modern shipping and warehousing logistics are improving for manufacturers across Canada.Get in touch with Encore Deliveries today online or call us at (905) 670-7111 to learn more about available services for warehouse storage and logistics as well as direct-to-consumer home delivery services.

Who We Are

Who We Are

Our Advantages

Our Advantages

Case Study

Case Study